Billiard Ball Manufacturing Process . Both phenolic resin and polyester billiard balls undergo a detailed manufacturing process to ensure optimal. In the case of phenolic resin balls, phenol and formaldehyde are combined with a catalyst to initiate polymerization. First, the raw phenolic resin is meticulously mixed. the global hub for billiard ball manufacturing is an essential aspect to explore in the context of pool, billiard, and snooker. the modern manufacturing process for billiard balls involves molding and shaping the raw materials into precise spheres. the process of creating billiard balls begins with the careful mixing of raw materials. in this article, we’ll explore how pool balls are made, delving into the materials, manufacturing processes, and quality. This process requires meticulous attention to detail to ensure uniformity in size and weight, which are essential for consistent gameplay. the manufacturing process of pool balls involves several intricate steps.

from eureka.patsnap.com

Both phenolic resin and polyester billiard balls undergo a detailed manufacturing process to ensure optimal. the process of creating billiard balls begins with the careful mixing of raw materials. the manufacturing process of pool balls involves several intricate steps. This process requires meticulous attention to detail to ensure uniformity in size and weight, which are essential for consistent gameplay. the modern manufacturing process for billiard balls involves molding and shaping the raw materials into precise spheres. In the case of phenolic resin balls, phenol and formaldehyde are combined with a catalyst to initiate polymerization. in this article, we’ll explore how pool balls are made, delving into the materials, manufacturing processes, and quality. First, the raw phenolic resin is meticulously mixed. the global hub for billiard ball manufacturing is an essential aspect to explore in the context of pool, billiard, and snooker.

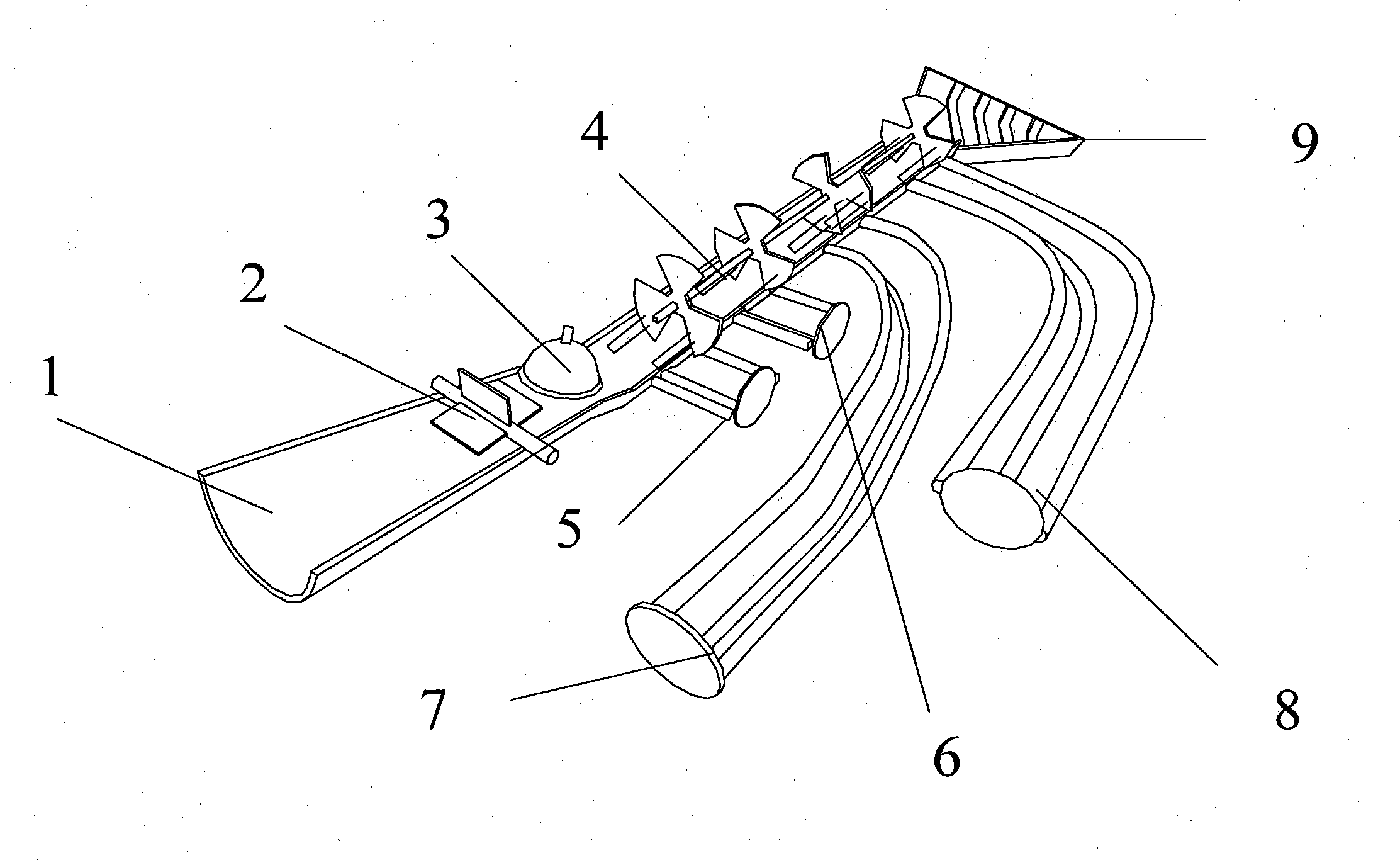

Fully automatic billiard ball placement machine Eureka Patsnap

Billiard Ball Manufacturing Process the manufacturing process of pool balls involves several intricate steps. the modern manufacturing process for billiard balls involves molding and shaping the raw materials into precise spheres. Both phenolic resin and polyester billiard balls undergo a detailed manufacturing process to ensure optimal. the process of creating billiard balls begins with the careful mixing of raw materials. In the case of phenolic resin balls, phenol and formaldehyde are combined with a catalyst to initiate polymerization. in this article, we’ll explore how pool balls are made, delving into the materials, manufacturing processes, and quality. This process requires meticulous attention to detail to ensure uniformity in size and weight, which are essential for consistent gameplay. First, the raw phenolic resin is meticulously mixed. the manufacturing process of pool balls involves several intricate steps. the global hub for billiard ball manufacturing is an essential aspect to explore in the context of pool, billiard, and snooker.

From www.youtube.com

How its made steel ball production process, skew rolling mill machine Billiard Ball Manufacturing Process This process requires meticulous attention to detail to ensure uniformity in size and weight, which are essential for consistent gameplay. the manufacturing process of pool balls involves several intricate steps. the modern manufacturing process for billiard balls involves molding and shaping the raw materials into precise spheres. Both phenolic resin and polyester billiard balls undergo a detailed manufacturing. Billiard Ball Manufacturing Process.

From www.youtube.com

Steel ball manufacturing process YouTube Billiard Ball Manufacturing Process This process requires meticulous attention to detail to ensure uniformity in size and weight, which are essential for consistent gameplay. the process of creating billiard balls begins with the careful mixing of raw materials. First, the raw phenolic resin is meticulously mixed. the manufacturing process of pool balls involves several intricate steps. In the case of phenolic resin. Billiard Ball Manufacturing Process.

From billiards.colostate.edu

Pool Ball Smoothness and Roundness Billiards and Pool Principles Billiard Ball Manufacturing Process Both phenolic resin and polyester billiard balls undergo a detailed manufacturing process to ensure optimal. the global hub for billiard ball manufacturing is an essential aspect to explore in the context of pool, billiard, and snooker. In the case of phenolic resin balls, phenol and formaldehyde are combined with a catalyst to initiate polymerization. First, the raw phenolic resin. Billiard Ball Manufacturing Process.

From www.youtube.com

How Pvc Ball is made in Factory // Pvc Ball manufacturing process YouTube Billiard Ball Manufacturing Process the manufacturing process of pool balls involves several intricate steps. Both phenolic resin and polyester billiard balls undergo a detailed manufacturing process to ensure optimal. the modern manufacturing process for billiard balls involves molding and shaping the raw materials into precise spheres. the process of creating billiard balls begins with the careful mixing of raw materials. . Billiard Ball Manufacturing Process.

From byjus.com

The motion of a billiard ball on a billiard table is a/an Billiard Ball Manufacturing Process the manufacturing process of pool balls involves several intricate steps. the global hub for billiard ball manufacturing is an essential aspect to explore in the context of pool, billiard, and snooker. the process of creating billiard balls begins with the careful mixing of raw materials. Both phenolic resin and polyester billiard balls undergo a detailed manufacturing process. Billiard Ball Manufacturing Process.

From www.youtube.com

How Bowling Balls Are Made. Interesting Bowling Ball Mass Production Billiard Ball Manufacturing Process the global hub for billiard ball manufacturing is an essential aspect to explore in the context of pool, billiard, and snooker. the manufacturing process of pool balls involves several intricate steps. the process of creating billiard balls begins with the careful mixing of raw materials. in this article, we’ll explore how pool balls are made, delving. Billiard Ball Manufacturing Process.

From www.youtube.com

Carbon Steel Balls, Brass Ball Manufacturing Process Video YouTube Billiard Ball Manufacturing Process In the case of phenolic resin balls, phenol and formaldehyde are combined with a catalyst to initiate polymerization. in this article, we’ll explore how pool balls are made, delving into the materials, manufacturing processes, and quality. the manufacturing process of pool balls involves several intricate steps. This process requires meticulous attention to detail to ensure uniformity in size. Billiard Ball Manufacturing Process.

From www.presidentialbilliards.com

Billiard Table Manufacturing Process Resources Presidential Billiards Billiard Ball Manufacturing Process the global hub for billiard ball manufacturing is an essential aspect to explore in the context of pool, billiard, and snooker. in this article, we’ll explore how pool balls are made, delving into the materials, manufacturing processes, and quality. First, the raw phenolic resin is meticulously mixed. Both phenolic resin and polyester billiard balls undergo a detailed manufacturing. Billiard Ball Manufacturing Process.

From www.youtube.com

Professional golf ball manufacture in Taiwan YouTube Billiard Ball Manufacturing Process First, the raw phenolic resin is meticulously mixed. This process requires meticulous attention to detail to ensure uniformity in size and weight, which are essential for consistent gameplay. the process of creating billiard balls begins with the careful mixing of raw materials. the manufacturing process of pool balls involves several intricate steps. the modern manufacturing process for. Billiard Ball Manufacturing Process.

From billiard-accessories.en.alibaba.com

Taishan Hongjie Billiards Products Manufacturing Factory billiard Billiard Ball Manufacturing Process In the case of phenolic resin balls, phenol and formaldehyde are combined with a catalyst to initiate polymerization. This process requires meticulous attention to detail to ensure uniformity in size and weight, which are essential for consistent gameplay. the process of creating billiard balls begins with the careful mixing of raw materials. the modern manufacturing process for billiard. Billiard Ball Manufacturing Process.

From www.ml-ball.com

Manufacturing ProcessMingliang Steel Ball Billiard Ball Manufacturing Process the modern manufacturing process for billiard balls involves molding and shaping the raw materials into precise spheres. the global hub for billiard ball manufacturing is an essential aspect to explore in the context of pool, billiard, and snooker. the process of creating billiard balls begins with the careful mixing of raw materials. First, the raw phenolic resin. Billiard Ball Manufacturing Process.

From www.youtube.com

steel ball manufacturing process, steel ball forming machine,steel ball Billiard Ball Manufacturing Process the process of creating billiard balls begins with the careful mixing of raw materials. the global hub for billiard ball manufacturing is an essential aspect to explore in the context of pool, billiard, and snooker. the modern manufacturing process for billiard balls involves molding and shaping the raw materials into precise spheres. Both phenolic resin and polyester. Billiard Ball Manufacturing Process.

From eureka.patsnap.com

Fully automatic billiard ball placement machine Eureka Patsnap Billiard Ball Manufacturing Process In the case of phenolic resin balls, phenol and formaldehyde are combined with a catalyst to initiate polymerization. the manufacturing process of pool balls involves several intricate steps. the global hub for billiard ball manufacturing is an essential aspect to explore in the context of pool, billiard, and snooker. the modern manufacturing process for billiard balls involves. Billiard Ball Manufacturing Process.

From www.youtube.com

Carbon Steel Ball, Stainless Steel Ball Manufacturing Process YouTube Billiard Ball Manufacturing Process Both phenolic resin and polyester billiard balls undergo a detailed manufacturing process to ensure optimal. In the case of phenolic resin balls, phenol and formaldehyde are combined with a catalyst to initiate polymerization. the manufacturing process of pool balls involves several intricate steps. This process requires meticulous attention to detail to ensure uniformity in size and weight, which are. Billiard Ball Manufacturing Process.

From www.jzequipment.com

Steel ball making process Billiard Ball Manufacturing Process This process requires meticulous attention to detail to ensure uniformity in size and weight, which are essential for consistent gameplay. Both phenolic resin and polyester billiard balls undergo a detailed manufacturing process to ensure optimal. in this article, we’ll explore how pool balls are made, delving into the materials, manufacturing processes, and quality. In the case of phenolic resin. Billiard Ball Manufacturing Process.

From www.youtube.com

High Quality Ball Manufacturing Process Overview YouTube Billiard Ball Manufacturing Process This process requires meticulous attention to detail to ensure uniformity in size and weight, which are essential for consistent gameplay. Both phenolic resin and polyester billiard balls undergo a detailed manufacturing process to ensure optimal. the global hub for billiard ball manufacturing is an essential aspect to explore in the context of pool, billiard, and snooker. In the case. Billiard Ball Manufacturing Process.

From www.nghexin.com

Grinding balls manufacturing process Melting, Molding and Heat treatment Billiard Ball Manufacturing Process In the case of phenolic resin balls, phenol and formaldehyde are combined with a catalyst to initiate polymerization. This process requires meticulous attention to detail to ensure uniformity in size and weight, which are essential for consistent gameplay. the global hub for billiard ball manufacturing is an essential aspect to explore in the context of pool, billiard, and snooker.. Billiard Ball Manufacturing Process.

From www.youtube.com

Billiard Ball Model What is Cobweb Model International Relations Billiard Ball Manufacturing Process the process of creating billiard balls begins with the careful mixing of raw materials. First, the raw phenolic resin is meticulously mixed. the modern manufacturing process for billiard balls involves molding and shaping the raw materials into precise spheres. the manufacturing process of pool balls involves several intricate steps. the global hub for billiard ball manufacturing. Billiard Ball Manufacturing Process.